How to Troubleshoot Common Garment Machinery Problems

Understanding the Basics of Garment Machinery

Garment machinery plays a crucial role in the textile industry, ensuring efficiency and quality in production. However, like any other equipment, these machines can experience problems that may disrupt operations. Understanding the basics of garment machinery is essential for troubleshooting common issues effectively. Knowing how each part functions and interacts with others is the first step in diagnosing potential problems.

Operators and maintenance staff should be familiar with the machine's manual, which provides valuable information about its components and their functions. Regular training and refreshers on machine handling can also prevent many common issues from arising. Armed with this knowledge, you can often identify problems before they escalate into major disruptions.

Identifying Mechanical Issues

Mechanical issues are among the most common problems encountered in garment machinery. These can range from minor adjustments to major component failures. Often, issues like unusual noises, vibrations, or irregular movements indicate mechanical problems. It's important to stop the machine immediately if such symptoms are noticed to prevent further damage.

Start by checking for loose bolts or misaligned parts. Regular maintenance schedules should include inspections for wear and tear on belts, gears, and other moving components. Timely replacement of worn-out parts can prevent costly breakdowns and production delays.

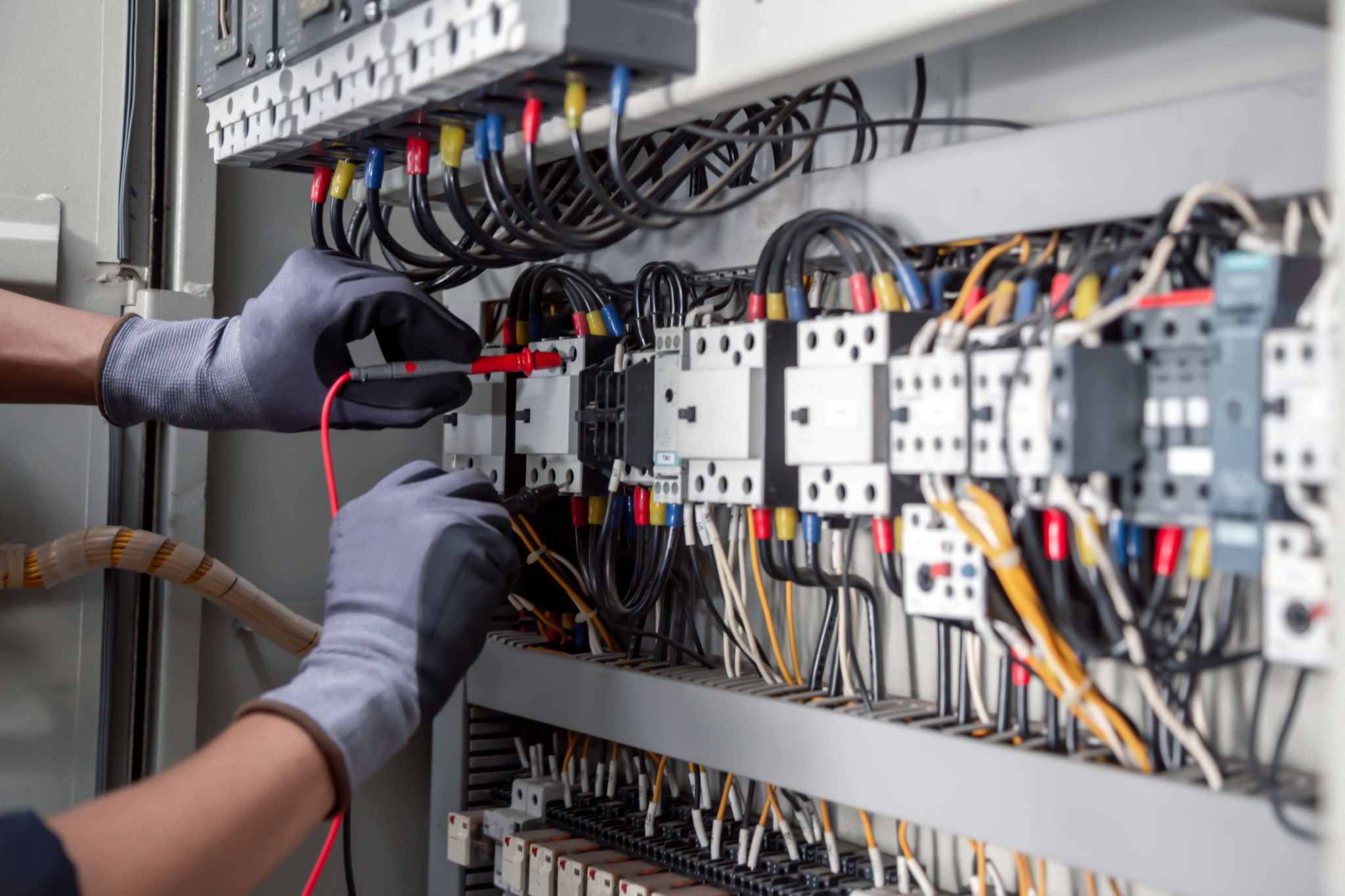

Resolving Electrical Problems

Electrical problems in garment machinery can be more challenging to diagnose but are equally critical to address. Common symptoms include inconsistent power supply, frequent tripping of circuit breakers, or malfunctioning control panels. These issues often stem from faulty wiring, damaged circuits, or worn-out electrical components.

Begin by inspecting the power supply and ensuring all connections are secure. Use a multimeter to check for continuity and voltage levels across different parts of the machine. Replace any damaged wires or components to restore proper functionality. Always ensure that electrical repairs are carried out by a qualified technician to avoid safety hazards.

Troubleshooting Software-Related Problems

Modern garment machinery often incorporates sophisticated software for enhanced functionality and precision. Software-related issues can manifest as errors in operation sequences or unexpected shutdowns. Keeping software updated is crucial in preventing these problems. Regular software updates can fix bugs and improve overall performance.

If a software issue arises, consult the machine's manual or contact the manufacturer for troubleshooting advice. Often, resetting the machine or reinstalling the software can resolve such issues. However, ensure that all data is backed up before performing any resets to avoid losing important information.

Preventive Maintenance Practices

Implementing a robust preventive maintenance program is key to minimizing garment machinery problems. Regular inspections and scheduled maintenance can help identify potential issues before they become serious. This includes keeping a detailed record of all maintenance activities and repairs performed on each machine.

Ensure that all operators and maintenance staff adhere to recommended guidelines for cleaning, lubricating, and adjusting machines regularly. This not only extends the life of the equipment but also ensures consistent production quality. By taking a proactive approach to maintenance, garment manufacturers can significantly reduce downtime and improve operational efficiency.