Top Innovations in Garment Machinery You Should Know

Revolutionizing the Textile Industry

The garment industry has witnessed remarkable innovations in machinery that have transformed production processes. These advancements have not only increased efficiency but also improved the quality of the final products. From automated cutting machines to smart sewing technologies, garment machinery is evolving rapidly.

In this blog post, we will explore some of the most groundbreaking innovations in garment machinery that are shaping the future of the textile industry. Understanding these advancements is crucial for manufacturers aiming to stay competitive in a fast-paced market.

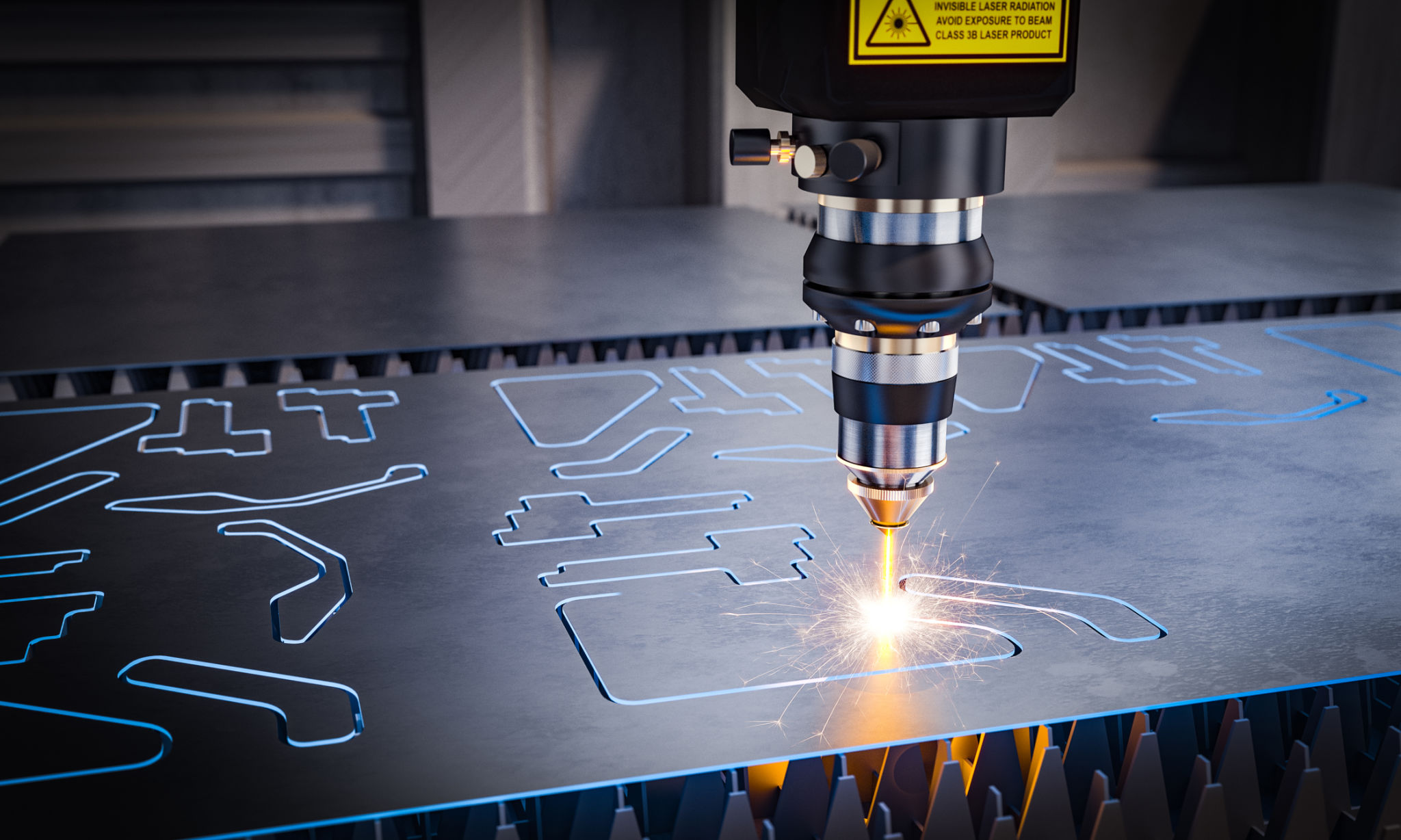

Automated Cutting Machines

Automated cutting machines have revolutionized the way fabrics are cut in the garment industry. These machines use advanced software to optimize fabric usage and reduce wastage. They are capable of cutting intricate patterns with high precision, ensuring consistency in production.

The integration of Computer-Aided Design (CAD) with these cutting machines allows for seamless transitions from design to production. This innovation has significantly reduced the time and labor involved in the cutting process.

Smart Sewing Technologies

Smart sewing machines are at the forefront of garment manufacturing, incorporating technologies such as Artificial Intelligence (AI) and the Internet of Things (IoT). These machines can automatically adjust settings based on the fabric type and desired stitch pattern, enhancing both speed and accuracy.

Additionally, smart sewing machines offer real-time monitoring and diagnostics, allowing for quick identification and resolution of issues. This leads to reduced downtime and increased productivity.

3D Knitting Machines

3D knitting machines are another cutting-edge innovation in garment machinery. These machines create garments in three dimensions, eliminating the need for cutting and sewing. The result is a seamless product that is both durable and comfortable.

This technology has opened new possibilities for designers, enabling them to experiment with complex patterns and structures that were previously unattainable with traditional methods.

Sustainable Dyeing Technologies

Environmental concerns have led to the development of sustainable dyeing technologies in the garment industry. New machinery uses waterless dyeing techniques and eco-friendly dyes, reducing the environmental impact of the dyeing process.

These innovations not only promote sustainability but also result in vibrant colors and improved fabric quality, appealing to environmentally conscious consumers.

The Future of Garment Machinery

As technology continues to advance, the garment industry is poised for even more exciting innovations. The integration of robotics and automation will further streamline production, while advancements in fabric technology will open new avenues for creativity and functionality.

Staying informed about these innovations is essential for industry professionals looking to maintain a competitive edge. Embracing these technologies will not only enhance efficiency but also lead to the creation of superior products.