Top Innovations in Textile Machinery: What to Expect in the Future

The textile industry has consistently evolved, driven by technological advancements that enhance efficiency, quality, and sustainability. As we look to the future, several innovations in textile machinery are set to redefine how fabrics are manufactured and utilized.

Automation and AI Integration

One of the most significant trends in textile machinery is the integration of automation and artificial intelligence (AI). Machines equipped with AI can monitor production processes in real-time, predict maintenance needs, and optimize operations to reduce waste. This not only improves efficiency but also cuts costs and enhances product quality.

Automation also facilitates the use of robotic arms for tasks like cutting, sewing, and packaging. These technologies reduce human error and increase production speed, allowing manufacturers to meet the growing demand for fast fashion.

Sustainability in Textile Production

Environmental concerns are pushing the textile industry towards more sustainable practices. Innovations in machinery are crucial for achieving eco-friendly production. New machines are being designed to minimize water and energy consumption, significantly reducing the environmental footprint.

Technologies such as waterless dyeing and energy-efficient weaving machines are becoming more prevalent. These innovations not only conserve resources but also appeal to environmentally-conscious consumers.

Advanced Fabric Development

The demand for advanced fabrics is on the rise, and textile machinery is evolving to meet this need. Machines are now capable of producing smart textiles imbued with electronic components that can monitor health, regulate temperature, or even change color.

Additionally, 3D knitting machines are revolutionizing the production of complex and customizable designs, offering new possibilities in fashion and industrial applications.

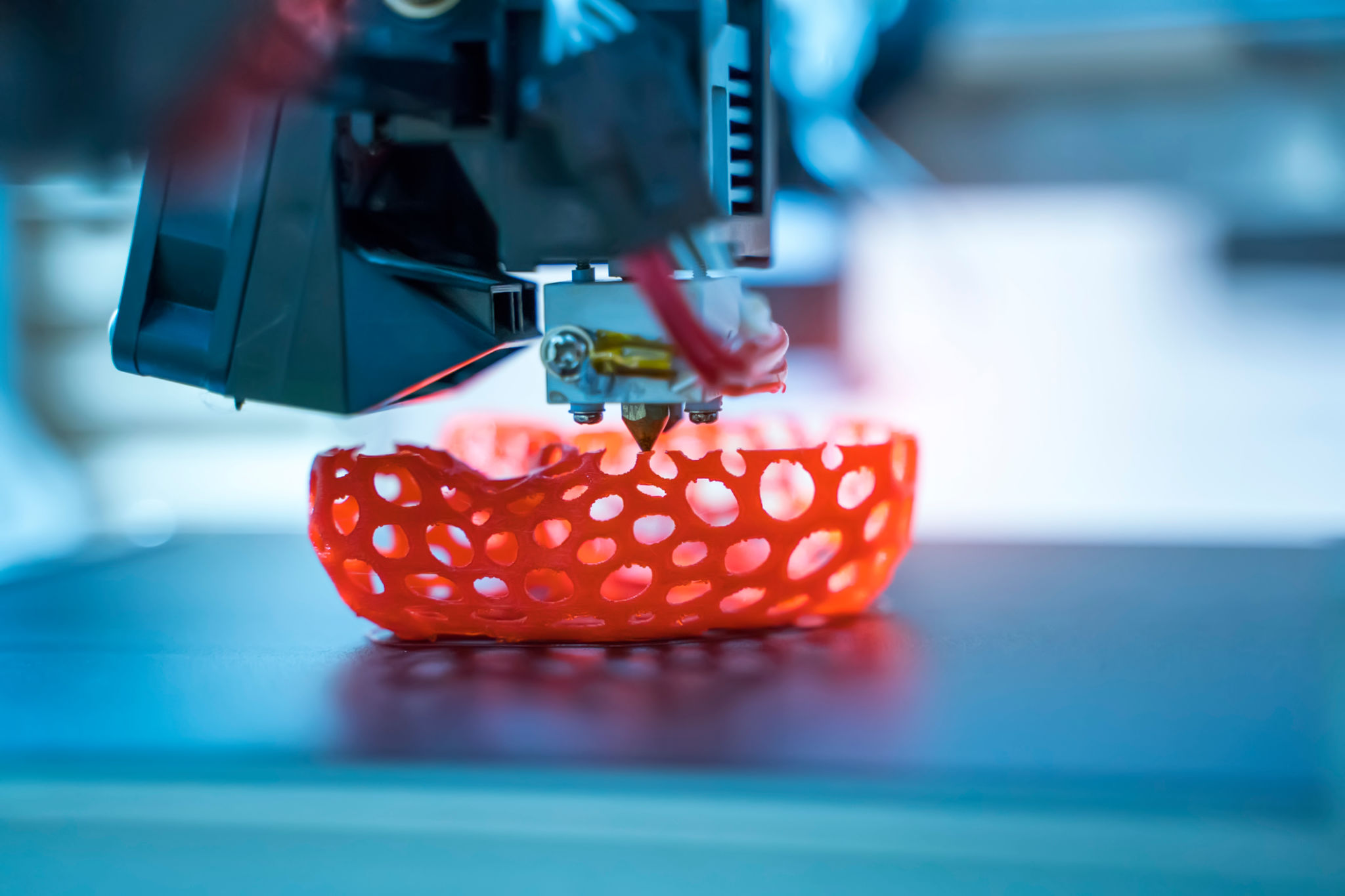

3D Printing and On-Demand Production

3D printing is making waves in the textile industry by enabling on-demand production of garments. This technology allows for the creation of intricate designs without the need for traditional sewing techniques, reducing fabric waste and storage costs.

The flexibility of 3D printing also means that consumers can have a greater role in the design process, leading to personalized and tailor-made clothing that aligns with individual preferences.

Digitalization and Connectivity

Digitalization is another key trend shaping the future of textile machinery. Connected machines can communicate with each other, providing a seamless flow of information across the production line. This connectivity ensures that any issues are quickly identified and addressed, minimizing downtime.

Moreover, digital platforms enable remote monitoring and control, allowing manufacturers to manage production from anywhere in the world. This level of flexibility is crucial for adapting to global supply chain challenges.

In conclusion, the future of textile machinery is bright, with innovations that promise to enhance efficiency, sustainability, and customization. As these technologies continue to evolve, they will undoubtedly transform the textile industry, paving the way for exciting possibilities and solutions to contemporary challenges.